The current and future applications are countless

Uncrewed Aerial Vehicles – drones – are just starting to show their possibilities. They can be navigated with impressive precision and coordination – made possible with components that guarantee reliability and perfect control, combined with light-weight design. The safety requirements for professional UAV applications operating in civil airspace correspond to those of regular planes and helicopters.

So when it comes to choosing components during the development phase, it’s crucial to use trusted, reliable and certifiable parts for ultimately also receiving the certification required for operation. That’s where Volz Servos comes in.

Ask the VOLZ experts

"The combination of small actuators for the UAV industry, high quality and reliability, certifiability and our experience and agility makes Volz Servos unique in the market."

Current and future applications for professional UAV

- Delivery of medical or technical materials within large clinical complexes or factory grounds or to remote areas

- Urban delivery

- Control, cleaning and maintenance of inaccessible areas or in dangerous environments

- Reconnaissance missions

- Observation and surveillance

- Police, fire brigade and military applications

The numerous existing laws and regulations on civil airspace at regional, national and international levels are subject to constant adjustments, especially with regard to the handling of uncrewed aerial vehicles. Even the smallest professional drones, maybe for last mile logistics or intralogistics, navigate and operate in civil airspace. With more than 40 years of experience, Volz speaks the language regarding these requirements and helps companies becoming fluent – with offering certifiable actuators for all kinds and sizes of drones in cooperation with our subsidiary AEE.

Certification is currently the biggest topic in the growing UAV sector. We at Volz Servos questioned ourselves how to maintain relationships with our customers beyond the prototype stage. With our subsidiary AEE, an EASA approved production (Part 21G), maintenance (Part 145) and alternative design organization (Part 21O), we are in the best position to meet our customers' needs – especially when it comes to certification, DO 178C, DO 254 and DO 160 requirements. Volz can take into account and comply with all regulations – so our actuators play an important role at the safe integration of UAV in civil airspace.

Why Volz Servos for your UAV?

First of all - matching YOUR needs

Our wide product range covers most cases of possible applications. Beyond that, we modify existing standard actuators or develop completely new customized solutions – as fast, flexible and agile as the aerial vehicles they are made for!

Wide range of products and options

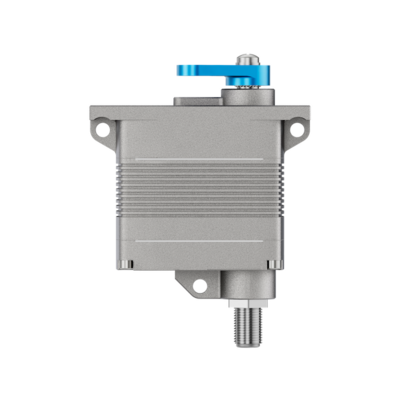

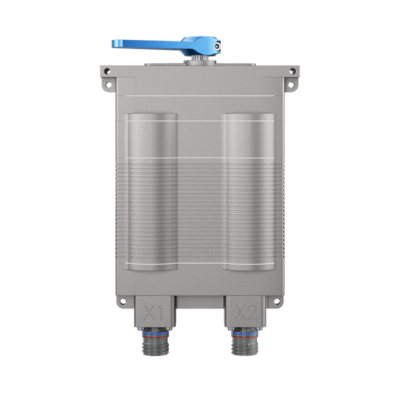

The Volz standard actuator portfolio offers sizes starting with the full brushless DA 15-N to the DA 58-D, the so called “Beast”, with various features such as health monitoring, fully brushless technologies, various interfaces etc.

Certifiable

With Aircraft Electronic Engineering (AEE), Volz Servos acquired an EASA approved production (Part 21G), maintenance (Part 145), and alternative design organization (Part 21O) in 2021. So Volz Servos meet the future requirements of the market for certifiable actuators!

Competent consulting

Discuss your requirements with our experts and learn how Volz develops your customized servos – or what kind of servos we can offer off-the-shelf.

Trusted

With nearly 40 years of experience in air mobility, Volz is best known as the leading manufacturer of electromechanical actuators for aerial vehicles.

Reliable and Redundant

Volz Servos impresses with its compact design combined with maximized actuating force, reliability and durability thanks to high-quality materials, technology and processing. The dual-channel design of the redundant Duplex Servos enables continuous operation, even if one of the two channel should fail.

Guaranteed quality

Our actuators are tested for several thousand hours of use. We manufacture them in Germany under the strictest quality controls (ISO 9001:2015, EN 9100 under implementation) to ensure the high requirements for quality and functional safety.

Monitoring

Various electrical interfaces offer the possibility of monitoring the operating status / health of the servo, for example by reading out the current, internal temperature, air humidity and more.

Our wide product range covers most cases of possible applications. Beyond that, we modify existing standard actuators or develop completely new customized solutions – as fast, flexible and agile as the aerial vehicles they are made for!

The Volz standard actuator portfolio offers sizes starting with the full brushless DA 15-N to the DA 58-D, the so called “Beast”, with various features such as health monitoring, fully brushless technologies, various interfaces etc.

With Aircraft Electronic Engineering (AEE), Volz Servos acquired an EASA approved production (Part 21G), maintenance (Part 145), and alternative design organization (Part 21O) in 2021. So Volz Servos meet the future requirements of the market for certifiable actuators!

Discuss your requirements with our experts and learn how Volz develops your customized servos – or what kind of servos we can offer off-the-shelf.

With nearly 40 years of experience in air mobility, Volz is best known as the leading manufacturer of electromechanical actuators for aerial vehicles.

Volz Servos impresses with its compact design combined with maximized actuating force, reliability and durability thanks to high-quality materials, technology and processing. The dual-channel design of the redundant Duplex Servos enables continuous operation, even if one of the two channel should fail.

Our actuators are tested for several thousand hours of use. We manufacture them in Germany under the strictest quality controls (ISO 9001:2015, EN 9100 under implementation) to ensure the high requirements for quality and functional safety.

Various electrical interfaces offer the possibility of monitoring the operating status / health of the servo, for example by reading out the current, internal temperature, air humidity and more.

Whenever and wherever performance, robustness and reliability are required, Volz’ products are the preferred solution. As light-weight as possible – as strong as required.

As medium-sized company, Volz is agile and flexible and also relies on decades of experience. The advantage for our customers: What we develop meets the requirements for the specific UAV project down to the last detail. From the very beginning, our experts work together with our customers as partners and in a spirit of mutual trust - from consulting, development and testing to production and service.“

By combining Volz Servos expertise in actuators technology with Thales Aerospace extensive experience in avionics and safety systems, this partnership aims to deliver a certified UAS that sets new standards for safety, reliability, and performance.

With eleven Volz actuators, Thales’s UAS100 long-range uncrewed air system can rely on actuation capabilities that meet the highest safety and reliability requirements. The DA 22 BLDC based servos will be fundamentally redeveloped under EASA regulations to achieve DAL B (Design Assurance Level - B).

Volz Servos offers dual redundant technology which aligns perfectly with our overall strategic focus on developing extreme reliability through redundancy. This is key to achieving our goal of perpetual flight. Skydweller CEO Dr. Robert Miller.

Skydweller Aero Inc. develops solar powered aircraft solutions capable of achieving perpetual flight with heavy and powerful payloads over long distances. Volz Servos is supplier for the project with the

-

DA-58-Duplex (for the ailerons on the 35 meters long wings)

-

DA-30-HT-Duplex (installed on the horizontal and vertical stabilizers)

A standard Volz actuator with special custom-made adaptions makes the Airboxer the most reliable concept that High Eye has ever created.

High Eye designed the Airboxer VTOL UAV to get in and out of locations out of reach for other systems: to collect valuable data or transports goods up to a payload of 7 kilograms.

A standard Volz actuator with special custom-made adaptions led to an extremely reliable aircraft. “The numbers don’t lie: The amount of non-recoverable incidents has never been lower”, says High Eye CTO Marijn van de Ruit.

“We are pleased with our now more than 15 years of good collaboration with Volz Servos, which included over 3.000 customized actuators for Schiebel’s S-100s. The Volz DA 26 are unmatched in reliability and crucial for our UAV projects enabling precise steering and safety.”

With Austrian Aerospace manufacturer Schiebel, Volz Servos can look back at a successful collaboration spanning over 15 years. For Schiebel’s CAMCOPTER® S-100, Volz has since delivered more than 3,000 specially customized versions of the Volz DA 26 actuators with redundant communication channels and redundant power supply. Schiebel's S-100s are designed to carry a variety of cameras, measuring devices or scanners for applications such as search and rescue, patrol missions or monitoring power lines.