Most valuable:

What our customers think

Of course, we are never tired of telling you about our decades of experience, the quality and reliability of our actuators and how they become certifiable.

But the most valuable testimonials are those of our satisfied customers.

Find out here, what companies appreciate about working with Volz and why they rely on our servos to bring their ambitious future air mobility projects to flight altitude.

As we continue to progress toward commercialization, it’s been crucial to find partners like Volz who have deep experience and expertise not only in the technology at hand, but in certification too.

BETA has teamed up with Volz Servos and its EASA certified subsidiary AEE (Aircraft Electronic Engineering GmbH) to complete the fly-by-wire system for the ALIA CTOL (Conventional Take-off and Landing, airport-to-airport transportation) and ALIA VTOL (Vertical Take-off and Landing / Advanced Air Mobility). Volz and AEE supply the projects with certifiable actuators according to the aviation standards applicable for each domain.

By combining Volz Servos expertise in actuators technology with Thales Aerospace extensive experience in avionics and safety systems, this partnership aims to deliver a certified UAS that sets new standards for safety, reliability, and performance.

With eleven Volz actuators, Thales’s UAS100 long-range uncrewed air system can rely on actuation capabilities that meet the highest safety and reliability requirements. The DA 22 BLDC based servos will be fundamentally redeveloped under EASA regulations to achieve DAL B (Design Assurance Level - B).

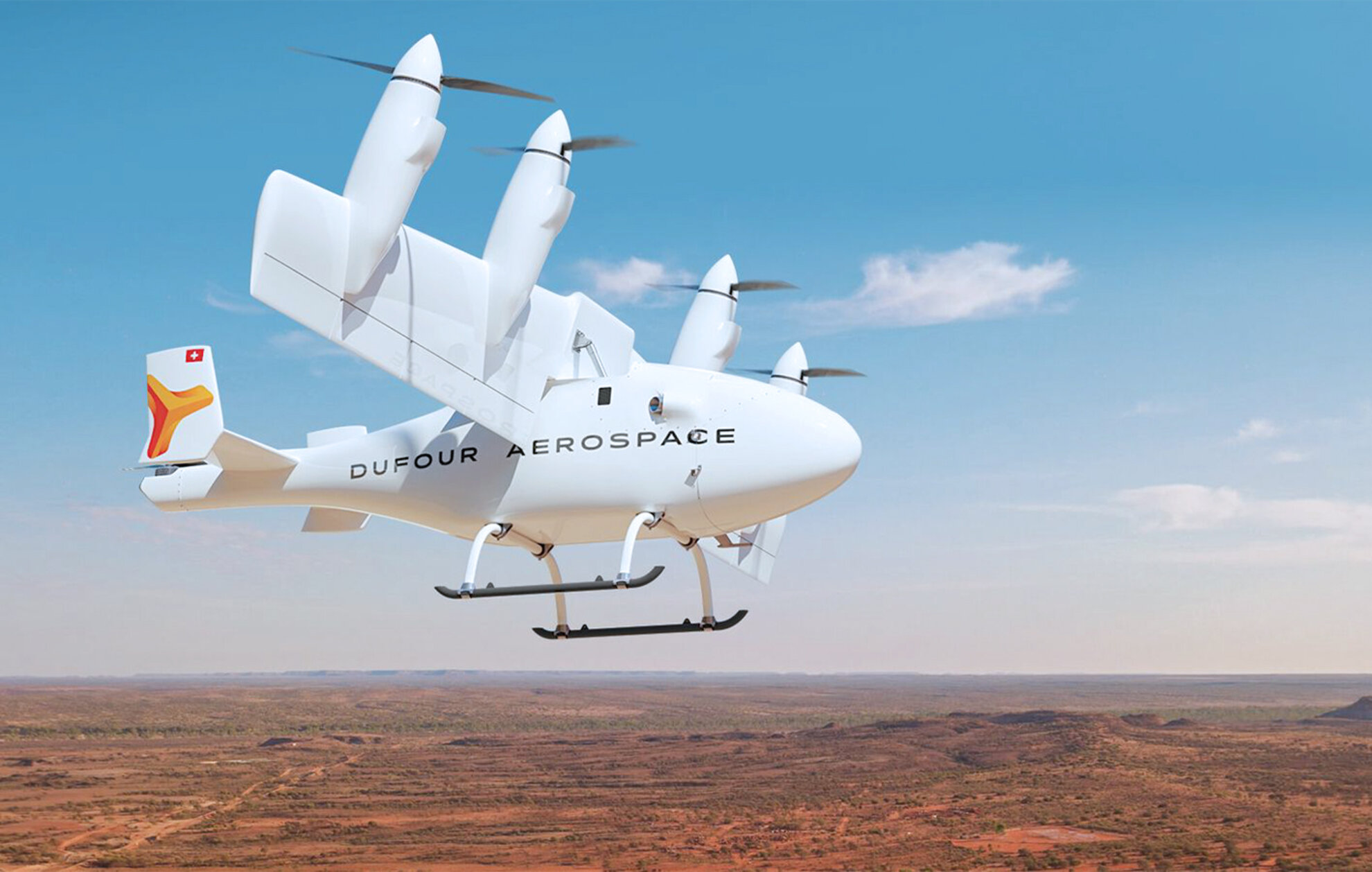

Volz are industry leaders in UAS actuation systems and offer a suite of robust and durable servos which Dufour are happy to utilise on their aircraft.

Dufour Aerospace’s tilt-wing aircraft is currently under development: Take-off and land vertically in the smallest space like a helicopter but fly as fast and economically as an airplane. Volz supplies the project with

A standard Volz actuator with special custom-made adaptions makes the Airboxer the most reliable concept that High Eye has ever created.

High Eye designed the Airboxer VTOL UAV to get in and out of locations out of reach for other systems: to collect valuable data or transports goods up to a payload of 7 kilograms.

A standard Volz actuator with special custom-made adaptions led to an extremely reliable aircraft. “The numbers don’t lie: The amount of non-recoverable incidents has never been lower”, says High Eye CTO Marijn van de Ruit.

Volz Servos offers dual redundant technology which aligns perfectly with our overall strategic focus on developing extreme reliability through redundancy. This is key to achieving our goal of perpetual flight. Skydweller CEO Dr. Robert Miller.

Skydweller Aero Inc. develops solar powered aircraft solutions capable of achieving perpetual flight with heavy and powerful payloads over long distances. Volz Servos is supplier for the project with the

-

DA-58-Duplex (for the ailerons on the 35 meters long wings)

-

DA-30-HT-Duplex (installed on the horizontal and vertical stabilizers)

“We are pleased with our now more than 15 years of good collaboration with Volz Servos, which included over 3.000 customized actuators for Schiebel’s S-100s. The Volz DA 26 are unmatched in reliability and crucial for our UAV projects enabling precise steering and safety.”

With Austrian Aerospace manufacturer Schiebel, Volz Servos can look back at a successful collaboration spanning over 15 years. For Schiebel’s CAMCOPTER® S-100, Volz has since delivered more than 3,000 specially customized versions of the Volz DA 26 actuators with redundant communication channels and redundant power supply. Schiebel's S-100s are designed to carry a variety of cameras, measuring devices or scanners for applications such as search and rescue, patrol missions or monitoring power lines.

“We've integrated Volz's servos across all our AUV, one of them has operated down to 4,840 m below the surface in the Porcupine Abyssal Plain, with the servos working just fine for the duration."

Not only high up in the sky, but also when it comes to extreme depth, reliable servos are crucial when it comes to control surfaces of underwater vehicles for exploration and scientific research missions. The National Oceanography Centre (NOC) in Southampton, UK, utilizes Volz' extreme depth-rated actuators in an Autosub Long Range Underwater Vehicle (AUV) nicknamed “Boaty McBoatface”, for survey work like underneath ice shelves local to the Thwaites Glacier in Antarctica.