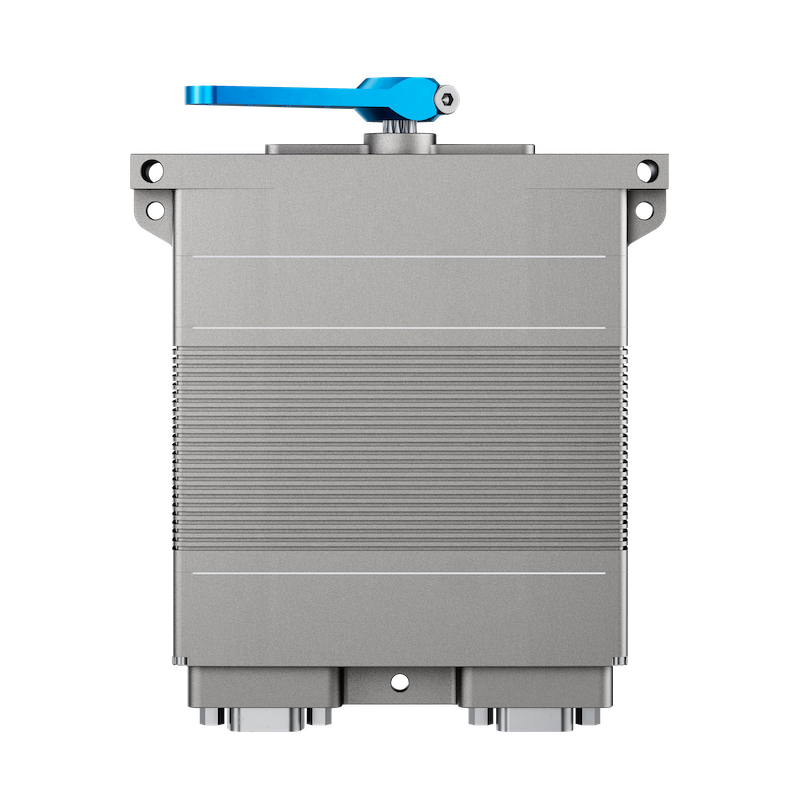

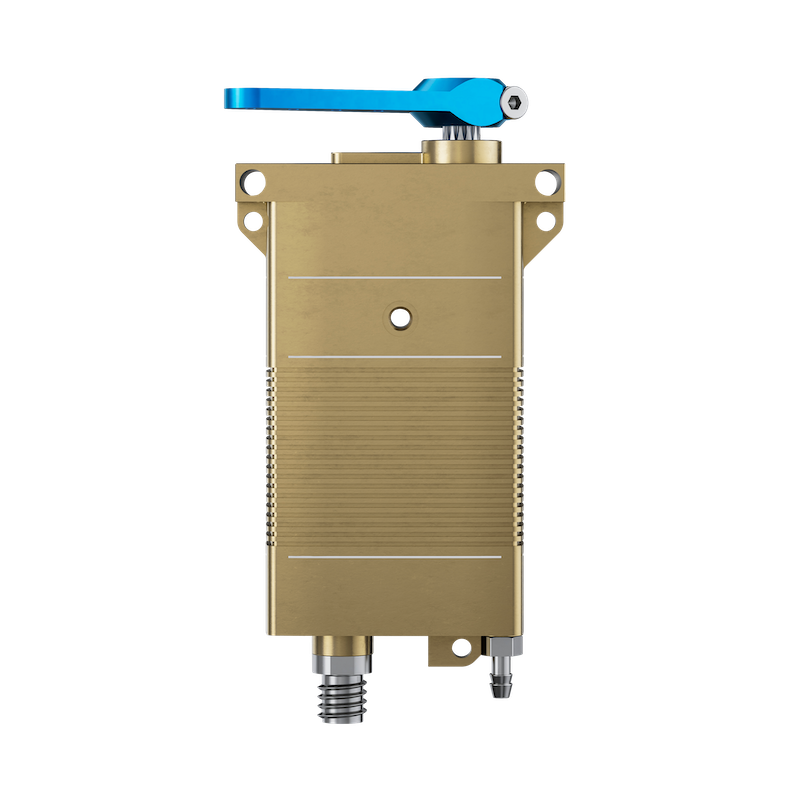

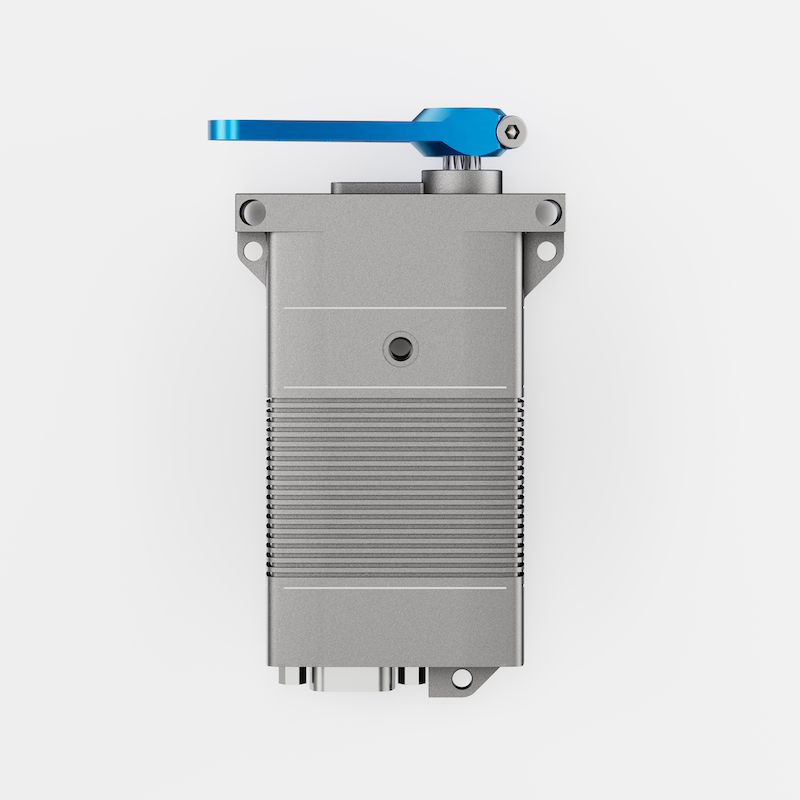

DA 26

12-32 Volts

To guarantee maximum safety and reliability, our DA 26 features a brushless motor and a contactless wear free position sensor. This means maximum service life with the greatest-possible power delivery and its design prevents electromagnetic emissions (EMI) caused by brush sparking. The housing made of saltwater-resistant aluminum is HART-coat treated, meets the IP-67 standard for water and dust sealing and provides an integrated Sub-D connector (MIL spec. circular connector or cable gland on request). Brackets integrated in the housing for horizontal and vertical assembly. 6-fold, ball-bearing supported, steel gear train, Drive shaft with ANSI multi-tooth (quadratic drive shaft on request).

The DA 26 series can be equipped with a standard PWM input (pulse width modulation) that has two different interfaces: a differential, galvanic isolated interface (opto-coupler) and a signle-ended interface with CMOS levels that is also used to program the servo parameters. Analog position feedback to detect the drive shaft position. A differential RS-422 PWM interface can be chosen instead of the opto-coupled interface.

The DA 26 with digital serial command interface (RS-485) receives its commands via a CRC secured protocol. It can return not only the shaft position in digital format, but also several diagnostic data such as the level of the supply voltage, current consumption and the temperature of the motor and electronics in digital form (optionally also the humidity within actuator case). These kind of diagnostic capabilities help to determine the health state of the actuators before, during and after deployment.

DA 26 actuators have been subjected to endurance tests of more than 3 million cycles (> 2,000 hours). Furthermore, successful tests based on MIL-STD 810F (vibration) and 810G (acceleration/shock) are performed. DA 26 actuators are used, for instance, in the Schiebel Camcopter S100.

Optional:

- RS-485 compatible, asynchronous serial command interface.

- Customized commands can be implemented on request.

- Redundant RS-485 interface with redundant power supply,

- RS-422 level compatible, differential PWM interface instead of the opto-coupler PWM interface.

- Humidity sensor (only in for RS-485 interface versions).

Technical Data

Choose your unit

General

| Width (Metric) | 26 mm |

| Width (Imperial) | 1.02 inch |

| Interface | PWM, RS 485 |

Specific

| DA 26‐30‐5024... | |

|---|---|

| Supply voltage (rated) | 28 VDC |

| Rated Current | 0.8 A |

| Peak Current | 1.3 A |

| Rated Torque (Metric) | 2.7 Nm |

| Rated Torque (Imperial) | 23.897 lbf‐in |

| Peak Torque (Metric) | 5 Nm |

| Peak Torque (Imperial) | 44.254 lbf-in |

| No Load Speed | 290 °/s |

| Rated Speed | 200 °/s |